To put it simply, forging is to smash metal into the shape you want, and casting is to melt the metal and then re-solidify it into the shape you want. Forging is to mechanically shape metal into the shape you want. (There are two methods, cold and hot.) Casting is to melt the metal and pour it into a prepared sand mold or mold. After cooling, it solidifies into the shape you want. .

Forging is a processing method that uses a forging machine to apply pressure to a metal blank to plastically deform it to obtain a forging with certain mechanical properties, certain shape and size, and is one of the two major components of forging (forging and stamping). Through forging, defects such as as-cast looseness produced by the metal during the smelting process can be eliminated, and the microstructure can be optimized. At the same time, due to the preservation of the complete metal streamline, the mechanical properties of forgings are generally better than those of castings of the same material. For important parts with high load and severe working conditions in related machinery, forgings are mostly used in addition to rolling plates, profiles or welded parts with simple shapes.

A processing method of using a forging machine to apply pressure to a metal blank to plastically deform it to obtain a forging with certain mechanical properties, certain shape and size. One of the two major components of forging. Through forging, the as-cast looseness and welding holes of the metal can be eliminated, and the mechanical properties of forgings are generally better than those of castings of the same material. For important parts in machinery with high load and severe working conditions, forgings are mostly used in addition to rolling plates, profiles or welded parts with simple shapes.

Forging can be divided into

①Open forging (free forging)

Using impact force or pressure to deform the metal between the upper and lower abutting irons (anvil blocks) to obtain the required forgings, there are mainly two types of manual forging and mechanical forging.

②Closed mode forging

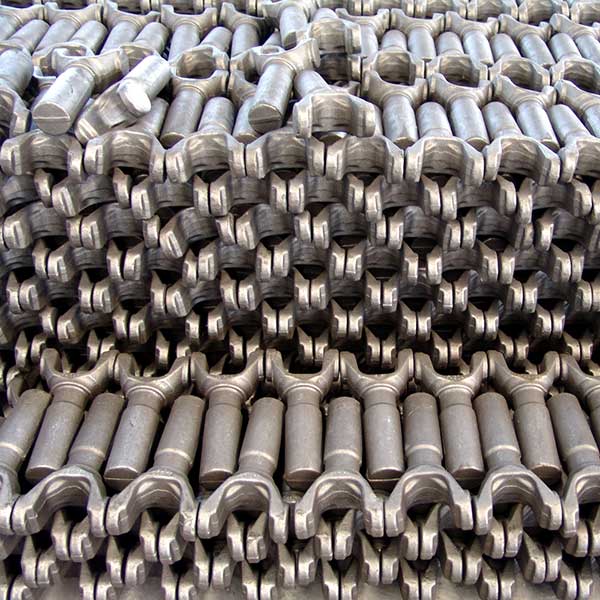

The metal blank is compressed and deformed in a forging die cavity with a certain shape to obtain a forging, which can be divided into die forging, cold heading, rotary forging, extrusion, etc. According to the deformation temperature, forging can be divided into hot forging (processing temperature is higher than the recrystallization temperature of the billet metal), warm forging (lower than the recrystallization temperature) and cold forging (normal temperature). Forging materials are mainly carbon steel and alloy steel of various compositions, followed by aluminum, magnesium, titanium, copper, etc. and their alloys. The original state of the material is bar, ingot, metal powder and liquid metal. The ratio of the cross-sectional area of the metal before deformation to the die cross-sectional area after deformation is called the forging ratio. Correct selection of forging ratio has a lot to do with improving product quality and reducing costs.

The difference between casting and forging

1. The production process is different

Casting is a forming. After the metal is melted into liquid, it is cast into a casting cavity suitable for the shape of the part, and after it is cooled, solidified and cleaned, the processing method of the part or blank is obtained. The foundry major focuses on the metal smelting process and the control of the process during the casting process.

Forging is slow forming. The method of applying pressure, extrusion, hammering and other methods to the metal blank with a forging machine makes the metal material in the plastic state a processing method of a workpiece with a certain shape and size. Forging is plastic forming in the solid state, which can be divided into hot working and cold working, such as extrusion, drawing, pier thickening, punching, etc.

2. Different uses

Forging is generally used in the processing of forgings of a certain shape and size. Casting is a relatively economical blank forming method, and is generally used on parts with complex shapes.

3. Different advantages and disadvantages

Forging advantages:

Through forging, defects such as as-cast looseness produced in the smelting process can be eliminated, and the microstructure can be optimized. At the same time, due to the preservation of the complete metal streamline, the mechanical properties of forgings are generally better than those of castings of the same material. For important parts with high load and severe working conditions in related machinery, forgings are mostly used in addition to rolling plates, profiles or welded parts with simple shapes.

Casting advantages:

1. It can produce parts with complex shapes, especially blanks with complex inner cavities.

2. Wide adaptability, metal materials commonly used in industry can be cast, ranging from a few grams to several hundred tons.

3. Wide source of raw materials and low prices, such as scrap steel, scrap parts, chips, etc.

4. The shape and size of the casting are very close to the parts, which reduces the amount of cutting and belongs to no cutting processing.

5. Widely used, 40% ~ 70% of agricultural machinery and 70% ~ 80% of the weight of machine tools are castings.

Casting Disadvantages:

1. The mechanical properties are not as good as forgings, such as coarse structure and many defects.

2. In sand casting, single-piece and small-batch production is labor-intensive.

3. The quality of castings is unstable, there are many processes, and the influencing factors are complex, which are prone to many defects.

Due to the different production processes of casting and forging, the uses of the processed products are different, and the advantages and disadvantages of the products are different. Forging uses hammering and other methods to make a metal material in a plastic state into a workpiece with a certain shape and size, and to change its physical properties. Casting is a process in which metal is melted into a liquid and then poured into a mold. After cooling, solidification, and cleaning, a casting of the desired shape can be obtained. It can be made into various objects with complex shapes.