Automotive and Truck

In automotive and truck applications, forged components are commonly found at points of shock and stress. Cars and trucks may contain more than 250 forgings, most of which are produced from carbon or alloy steel. Forged engine and powertrain components include connecting rods, crankshafts, transmission shafts and gears, differential gears, drive shafts, clutch hubs, and universal joint yokes and crosses. Forged camshafts, pinions, gears, and rocker arms offer ease of selective hardening as well as strength. Wheel spindles, kingpins, axle beams and shafts, torsion bars, ball studs, idler arms, pitman arms, steering arms, and linkages for passenger cars, buses, and trucks typify applications requiring extra strength and toughness.

Aerospace

High strength-to-weight ratio and structural reliability improve performance, range, and payload capabilities of aircraft. That’s why ferrous and nonferrous forgings are used in helicopters, piston-engine planes, commercial jets, and supersonic military aircraft. Many aircraft are “designed around” forgings, and contain more than 450 structural forgings as well as hundreds of forged engine parts. Forged parts include bulkheads, wing roots and spars, hinges, engine mounts, brackets, beams, shafts, bellcranks, landing-gear cylinders and struts, wheels, brake carriers and discs, and arresting hooks. In jet turbine engines, iron-based, nickel-base, and cobalt-base superalloys are forged into buckets, blades, couplings, discs, manifolds, rings, chambers, wheels, and shafts–all requiring uniformly high-yield tensile and creep rupture strengths, plus good ductility at temperatures ranging between 1,000 and 2,000°F. Forgings of stainless steels, maraging steels, titanium, and aluminum find similar applications at lower temperatures. Forged missile components of titanium, columbium, super alloys, and refractory materials provide unduplicated mechanical and physical properties under severe service conditions. Aluminum structural beams for boosters, titanium motor cases, and nuclear-engine reactor shields and inflatable satellite launch canisters of magnesium are used in the space shuttle program.

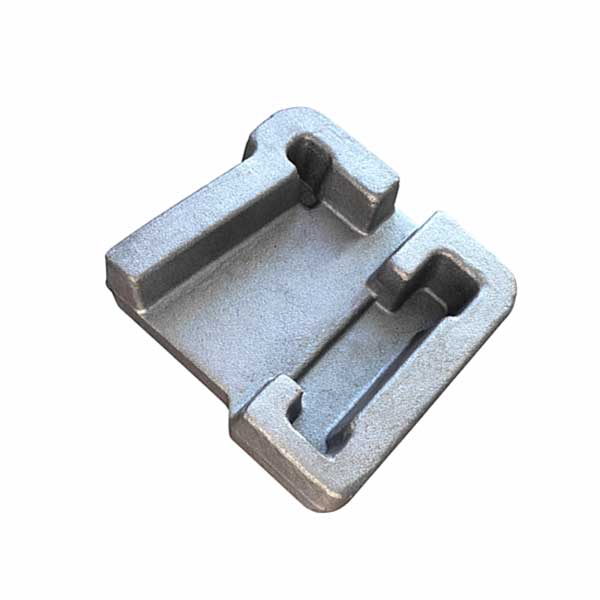

Off-Highway and Agricultural

Strength, toughness, machinability, and economy account for the use of ferrous forgings in off-highway and heavy construction equipment, and in mining machinery. In addition to engine and transmission parts, forgings are used for gears, sprockets, levers, shafts, spindles, ball joints, wheel hubs, rollers, yokes, axle beams, bearing holders, and links. Farm implements, in addition to engine and transmission components, utilize key forgings ranging from gears, shafts, levers, and spindles to tie-rod ends, spike harrow teeth, and cultivator shanks.

Ordnance

Forged components are found in virtually every implement of defense, from rifle triggers to nuclear submarine drive shafts. Heavy tanks contain more than 550 separate forgings; The majority of 155-mm, 75-mm, and 3-in. shells as well as mortar projectiles contain at least two forged components.

Valves and Fittings

For valves and fittings, the mechanical properties of forgings and their freedom from porosity are especially suited to high-pressure applications. Corrosion and heat-resistant materials are used for flanges, valve bodies and stems, tees, elbows, reducers, saddles, and other fittings. Oilfield applications include rock cutter bits, drilling hardware, and high-pressure valves and fittings.

Industrial, Hardware and Tools

Stationary and shipboard internal combustion engines include forged crankshafts, connecting rods, caps, camshafts, rocker arms, valves, gears, shafts, levers, and linkages. Outboard motors, motorcycles, and power saws offer examples of the intensive use of forgings in smaller engines. Industrial equipment industries use forgings in materials handling systems, conveyors, chain-hoist assemblies, and lift trucks.

“Forged” is the mark of quality in hand tools and hardware. Pliers, hammers, wrenches, and garden implements, as well as wire-rope clips and sockets, hooks, turnbuckles, and eye bolts are common examples. Strength, resistance to impact and fatigue, and excellent appearance are reasons why forgings have been the standard of quality since the earliest of times. The same is true of surgical instruments. Special hardware for electrical transmission and distribution lines is subject to high stresses and corrosion. For strength and dependability, forgings are used for parts such as pedestal caps, suspension clamps, sockets, and brackets.