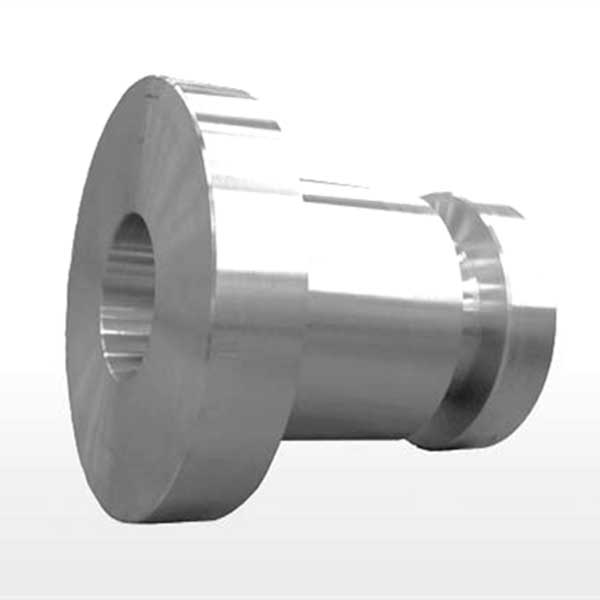

Pipe joint forgings require that each part be uniform without any porosity, inclusions or other imperfections. The components produced by this method have a high ratio of strength to weight.

These components are commonly used in pipeline construction. Advantages of pipe joint forgings are extendable length, shrinkable cross section; retractable length, stretchable cross section; variable length, variable cross section.

The types of forgings are: free forging / hand forging, hot forging / precision forging, upsetting, rolling and die forging.

Although the forging technology of pipe joint forgings has been greatly developed, and computer technology is used to assist in optimizing the fluid geometry design of the structural design and casting process, it is still extremely difficult to achieve good quality requirements.

During the forging of pipe joints, the metal cast into the cavity may shrink, separate or vent during solidification, which makes the “cast” forgings unacceptable for demanding environmental applications. Shrinkage occurs in two processes, where the metal at a temperature above the melting point shrinks as it cools, the forging component, and then further shrinks during solidification. The molten metal compensation is increased once, but the compensation during solid-state cooling is increased by size.

Reducing friction not only saves energy but also increases mold life. Due to the relatively uniform deformation, forgings help to improve the structural properties of forging products, and one of the important measures to reduce friction is to use lubrication. The lubricant used varies depending on the forging process of the forging and the difference in operating temperature. Glass lubricants are mostly used in high temperature alloys and titanium alloy forging. For hot forging of steel, water-based graphite is a widely used lubricant. For cold forging, due to the high pressure, it is often necessary to carry out phosphate or oxalate treatment before forging.

Search

OFFICE HOURS:

Mon-Fri 8:30-17:30

Contact us

Tel:+86-379-65505200

Mob.: +86-18538887499

E-mail: sales@jhindustrial.cn

Address: Luolong Industrial District, Luoyang City, Henan Province, China, 471000