Forging die design

1. The main influence of mold shape on metal deformation and flow is as follows:

1) control the final shape and size of forgings;

2) control the flow direction of metal;

3) control the plastic deformation zone;

4) improve the plasticity of metal;

5) control the billet instability and improve the forming limit.

2. Analyze the metal flow process in open die forging, the effect of flanging groove and the influence of the height and width of the bridge of the flanging groove on the metal flow:

The three stages of the metal flow process in open die forging:

a) upsetting stage

b) full mold chamber stage

c) surplus metal is pressed into the flanging groove;—- -flying groove including bridge and warehouse.

The main function of the bridge is to prevent metal outflow and force the metal to fill the mold.In addition, the flash thickness is reduced so that it can be removed in the subsequent process.The role of the bin is to accommodate excess metal, so as to avoid metal flow to the parting surface, the impact of the upper and lower die against.The wider the bridge, the smaller the height and the greater the resistance.In order to ensure that the metal is full of the mold chamber, the bridge resistance is expected to be larger;However, if it is too large, the deformation resistance will be large, so the resistance should be appropriate.

3.Analysis when the closed die forging billet volume and mould chamber volume change on the forging size:

The influence of the closed die forging, ignoring longitudinal flash material loss, if there is a deviation between blank and die chamber volume volume, the forging dimension will change, the influencing factors of volume has two aspects: on the one hand is blank actual volume changes, mainly under the billet diameter and length tolerance, the quantity of burning, such as the change of the actual forging temperature;On the other hand, it is the change of the actual volume of the die chamber, which mainly includes the wear of the die chamber, the change of elastic deformation caused by the change of working load of equipment and die, and the change of forging die temperature.

4. Impact of striking energy and die pressure on forming quality:

1) in the case of no range limiting device, when striking energy is appropriate, the forming will be good, while if it is too large, it will produce flash, and if it is too small, it will be dissatisfied.

2) in closed die forging, adding a range limiting device to the blank with accurate volume can improve the situation of flanging caused by excessive striking energy, so as to obtain well-formed forgings.

3) for the mechanical press, due to a certain stroke, the size of the die pressure and forming conditions depends on the size of the billet volume.

5. Die forging process:

1) blanking;

2) heating;

3) die forging;

4) hot cutting edge;

5) cooling;

6) heat treatment;

7) surface cleaning;

8) final inspection;

9) warehousing.

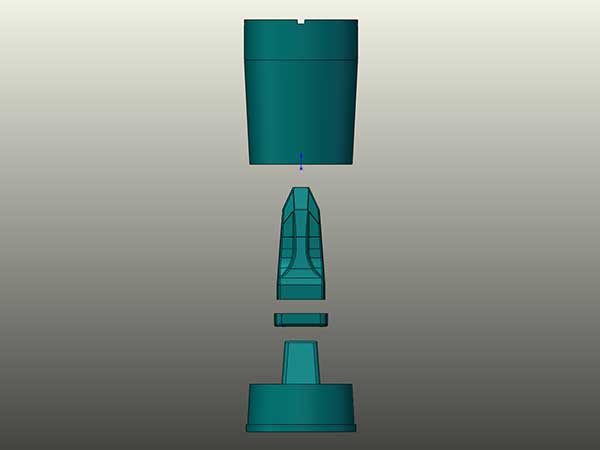

6. Die forgings drawing design :

(1) parting surface

(2) remaining blocks, allowance and tolerance of forgings

(3) Angle of die forgings

(4) rounded corners of forgings

(5) punching with leather

(6) drawing of forgings.( Determine the parting surface: a. it is easy to find the relative dislocation of the upper and lower molds; b.the metal is easy to fill the groove; c. improve the metal utilization rate; d. simplify the mold manufacturing.

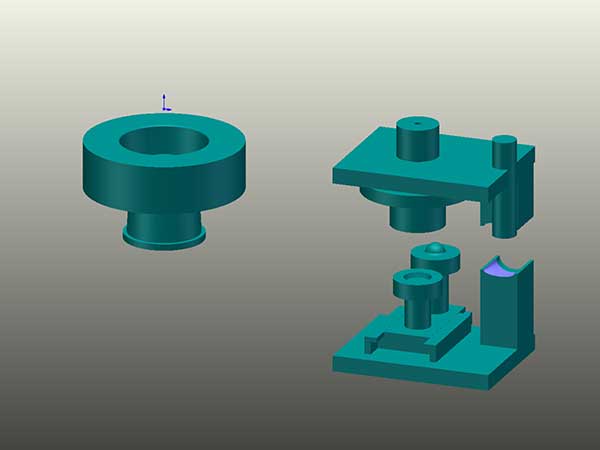

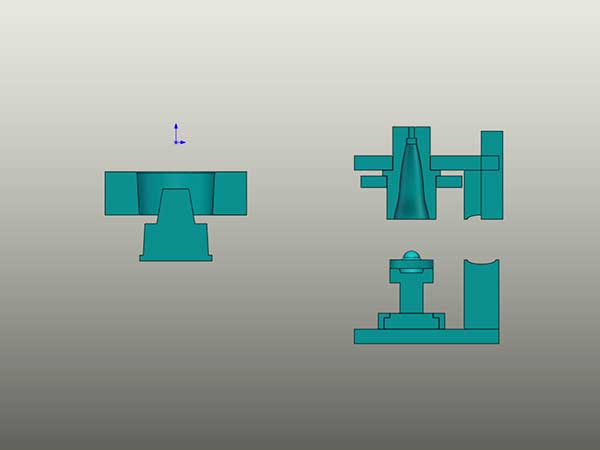

7.There are several differences between mold design and simple mold:

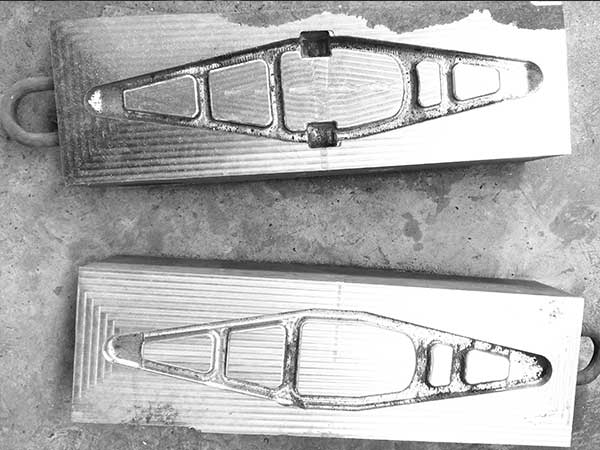

1) flanging groove

2) guiding and positioning device

a. guide column

b. guide lock

c.guide column and guide lock connection

d. guide sleeve

3) module size and gate.

8.Die design process :

(1). Design forging drawing

(2). Design hot key drawing

(3). Preselect flash groove, analyze forging section and draw and calculate blank drawing

(4).Confirm the blank size

(5). Determine the blank size

(6). Design the blank die chamber

(7). Determine the main parameters of forgings.

(8). Select die forging equipment specification

(9). Design flash groove

(10) design the pre-forging die chamber, etc.